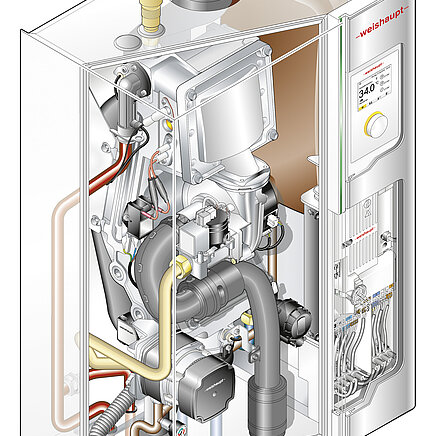

Hydraulic and mechanical components on the left, electronic components on the right

The vertical separation of functions means the individual components, such as the burner, heat exchanger, pump, etc. are clearly arranged and readily accessible for maintenance. There is a watertight separation between the hydraulic and electronic components.

Dead plumb, guaranteed – even when installed single handedly

The new gas-fired condensing boiler can be installed and commissioned by one person. The protective styrofoam packaging has two practical grip holes, which allow the boiler – that only weighs 41 kg – to be easily lifted up to the mounting bracket. The boiler can be quickly hung dead plumb, and even shifted 10 mm horizontally or vertically, thanks to the installer-friendly mounting bracket and the two-point levelling mechanism. This is particularly helpful in everyday practice when holes are seldom drilled into the wall with millimetre precision.

Outstanding efficiency thanks to high-capacity heat exchanger

The boiler has a premium quality, high-capacity sand-cast aluminium-silicone heat exchanger. It is notable for its high heat conductivity (6.7 times better than stainless steel), efficiency, robustness, and durability. The 6600 cm2 surface of the heat exchanger has a well-thought-out nubbed structure that draws the largest amount of energy from the combustion gases. This results in a nominal efficiency of 110.1 % (HHV) or 99.2 % (LHV) at a system temperature of 40/30 °C.

SCOT combustion control with extended turndown range

The self-calibrating Weishaupt SCOT-System ensures combustion is always optimal even when gas constituents vary. The new-generation boilers can turn all the way down to 1.9 kW. A big advantage when partial load operation is becoming ever more important, since many modern buildings require outputs below 4 kW over long periods of time.

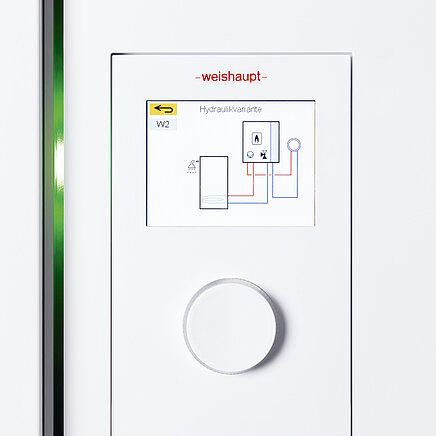

Assistant for fast commissioning

The commissioning assistant will check some constraints and then suggest the available hydraulic variants. Once the desired hydraulics have been selected, many of the control parameters will be preset. That simplifies commissioning and saves time.

Modular energy management system (WEM)

Weishaupt's modular energy management system (WEM) is universally employable and expandable – even with complicated systems. The standard controls in a gas-fired condensing boiler encompass a heating circuit and a DHW circuit. Up to 24 additional heating circuits can be added. Each additional heating circuit is connected to the central controller via an expansion module.

Easy operation via app or browser

Thanks to its standard LAN port and the Weishaupt Energy Management Portal, the new gas-fired condensing boiler can communicate easily and securely over the internet with computers, smartphones, or tablets. The current high security standards are adhered to. Of course, the boiler can also be controlled by an optional room controller.