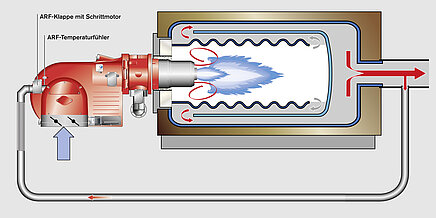

A 4LN-version burner is equipped with a flue gas recirculation system whose control components are integrated with the burner. Specially designed mixing assemblies and digital combustion management ensure that the key characteristics of Weishaupt burners – reliable ignition, a high degree of flame stability, and safe operation – remain very much to the fore.

Flue gas recirculation (FGR) reduces the oxygen concentration per cubic metre of air, increases the air flow speed, shortens dwell times for combustion gases in the hot reaction zone, and lowers flame temperatures. This all leads to a cut in NOx emissions.

The critical factor is the precise dosing of the recirculated flue gas. The W-FM 200 combustion manager is best placed to control this. With just two additional components – a flue gas temperature sensor and a butterfly valve – and some additional software, the W-FM 200 can control the flow of flue gas so that the correct amount will be fed into the combustion air under all operating conditions.

Flue gas temperature is also crucial in determining the volume of flue gas to be recirculated. The temperature of the flue gas affects its density and thus the mass flow rate. The flue gas temperature is measured continuously to ensure stable burner operating behaviour and consistently low NOx levels. Variations in temperature are compensated for automatically by adjustments to the FGR butterfly valve. As well as controlling the FGR butterfly valve, the W-FM 200 combustion manager’s software has parameters at hand that allow additional adjustments to be made.