Locher Brewery: Modernization with three fuels and four operating modes

The Locher family has been brewing Appenzeller beer since 1886 and is now in its fifth generation. Today, the award-winning range includes over 40 different beer specialities. The Locher brewery delivers throughout Switzerland and also exports selected specialities. At its main location in the heart of Appenzell, around 200 employees are committed to the region and its traditions every day.

In 2021, Locher launched the food upcycling brand “brewbee.” This brand aims to make good use of by-products from the brewing process. The in-house production facility now manufactures a wide range of products such as chips, pizzas, muesli, lasagna, ravioli, and plant-based products. With “brewbee,” the Locher brewery is sending a strong signal for sustainability and the innovative use of brewery by-products, thereby reducing food waste and opening up new markets.

Sustainability was also a priority in the modernization of steam generation. Here, biogas from the brewery's wastewater is used as fuel. Natural gas and heating fuel oil are used as additional fuels. A Weishaupt monarch® WM-GL 30 4LN simultaneous burner with 10,240,000 BTU/hr (3,000 kW) has replaced a previous gas burner on the steam boiler. The following operating modes are possible:

- Natural gas in single operation

- Natural gas and biogas in simultaneous operation

- Heating fuel oil in single operation

- Heating fuel oil and biogas in simultaneous operation

When operating with heating oil, an external flue gas re-circulation (FGR) system reduces nitrogen oxide emissions. In addition, the burner is equipped with speed control, i.e., a frequency converter attached to the blower motor. This significantly minimizes electrical energy consumption.

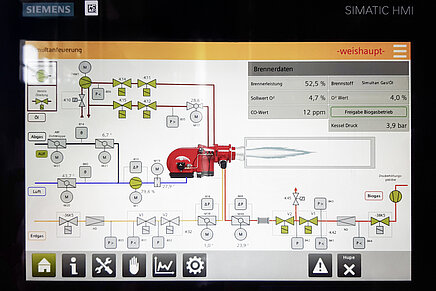

The scope of delivery also included the burner control system manufactured and tested by Weishaupt with the W-FM1000 CMS digital combustion manager. Visualization and operation are realized with a touch panel.

Other reference sites of this type:

Bitburger Brewery: Steam generation with Weishaupt

Heat supply for Bremen's Überseestadt district