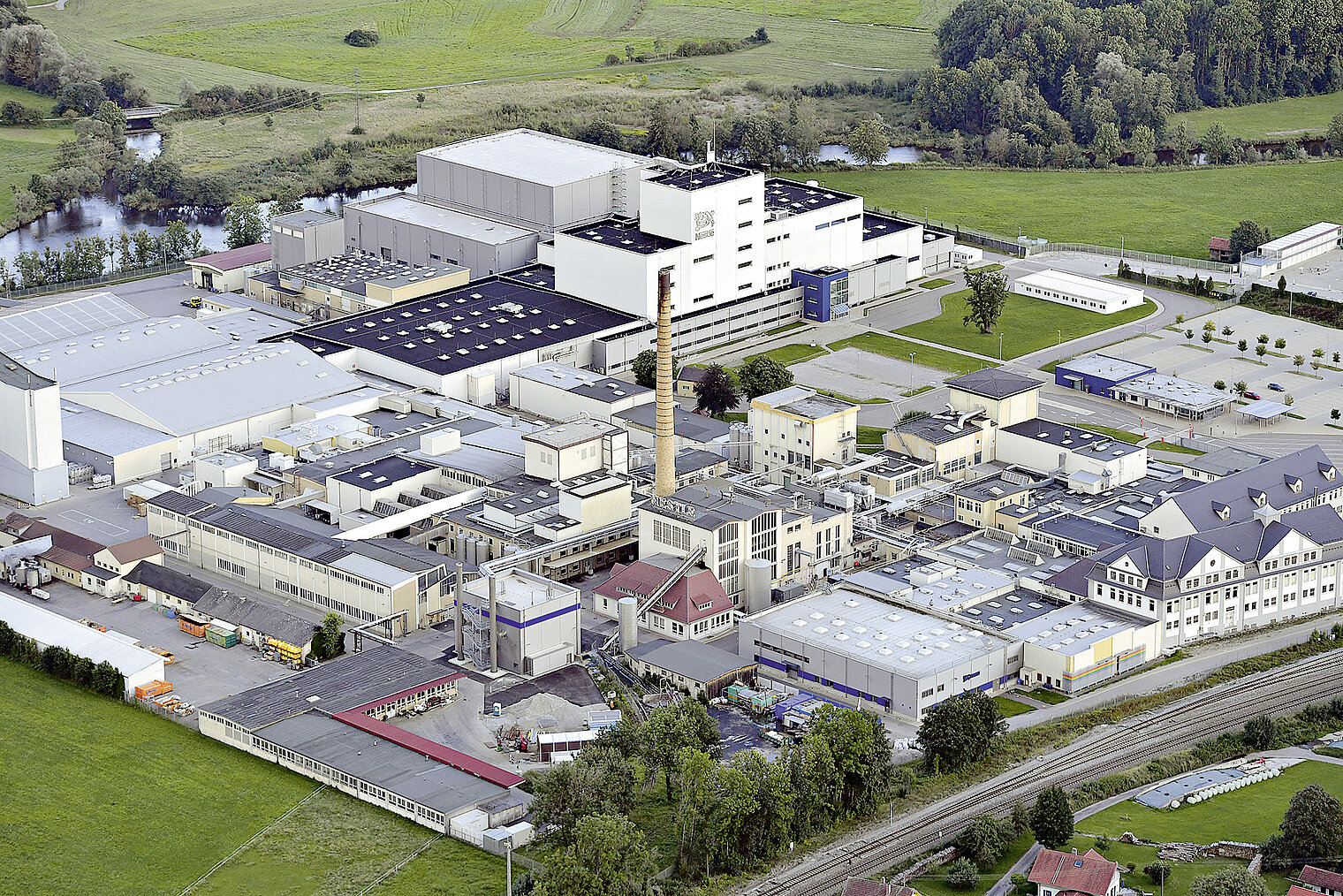

Nestlé plant in Biessenhofen: New boiler house

Many production steps at the Nestlé plant in Biessenhofen (Allgäu) require steam: it is used, for example, in sterilization, heating products, and various drying processes.

Since 2016, a new Boiler house on the factory premises has been supplying the nearly 100,000 tons of steam consumed here annually. At the heart of the plant are two boilers with Weishaupt WKmono-G80 gas burners as energy generators. The large burners with speed and oxygen control each have a firing capacity of 13 megawatts and produce less than 100 milligrams of nitrogen oxides (NOx

) per cubic meter of exhaust gas.

Nestlé primarily manufactures food for infants and young children in Biessenhofen. The plant, which employs 800 people, is a center of excellence for hypoallergenic infant nutrition within the global corporation.

The investment in the new energy technology has ushered in a new era at the Nestlé site. The boilers with gas burners are replacing coal-fired systems from the 1950s and 1960s. As a result of this measure, Nestlé has reduced Carbon dioxide Emissions

at the site by 12,000 tons per year.

Weishaupt large burners were chosen in particular because of their high product quality – for example, the burner housings are made of cast aluminum – and low Nitrogen oxide Emissions

. Biessenhofen already had experience with products from the energy technology manufacturer based in Schwendi: a Weishaupt burner has been used for some time to heat drying air in production.

Weitere Referenzen dieser Art:

Bitburger Brewery: Steam generation with Weishaupt

Neue Heimat für gute Ideen und saubere Energie